Profile:

Our company is a part of large diversified group and we are professional

manufacturer of High Quality Circular Knitting Machine since 1987 from

Taiwan, also we set up Composite factory in China to serve more

textile knitting mills. CE & ISO-9001 Certification with compliance with EU

regulations for all our machinery.

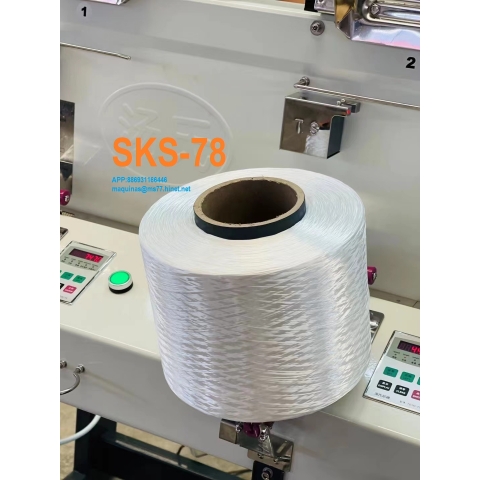

SKS-78. Thread Cone to Yarn Cone winder machine

Application:

1. SKS-008 High speed thread winding machine is applicable for winding Cotton

yarn, sewing thread, embroidery thread, nylon thread ,etc.

2. This machine features availability of computer-based separate control of each

single spindle, a frequency –change slotted spool yarn guide device, an electro-magnetic

tension force control system, a pump-based cycling –type oiling device ,…etc !

3. Characteristics of a good shape formation , high efficiency , easy operation , assured

safety and reliability and broad applicability , and so on.

4/ Best of all, each machine has 4 Mitsubishi inverter protection devices.

.jpg)

.jpg)

.jpg)

Computer yarn-length measurement.

1. Yarn length measured by computer, accuracy +1%.

2. Advanced touch panel, adjustable yarn winding speed, 400-1000m/min, can set winding

length, winding quantity, tanker speed, etc., can be displayed in advanced touch panel.

3. Each spindle is equipped with electronic tension, which can be adjusted on the

touch screen, and a manual tensioner.

4.Yarn pattern can be manually adjusted.

5. Non-contact light rod detector, stop yarn breaking automatically.

6. Each machine is equipped with independent oil drum, automatic oil circulation,

7. 30 years of machinery manufacturing, high efficiency, high quality, easy to operate!

.jpg)

Automatic lubrications system.

1. Threads are being uniform lubricate, thanks to the constant yarn speed, the oiling roller speed is adjustable.

2. Release the tension from beginning to the end; it makes the winded package good appearances

3. LED display easy operation.

.jpg)

.jpg)

Circulating oil device.

1. Keep always the full level of oil to each spindle.

2. Big-scale return oil trough and oil fender to filter without pollution and oil waste.

3. One oil filter is devoiced for every oil wheel to reduce the oil slinging out.

4. Each machine has its own oil tank

5. Detachable filter, easy to clean.

Configured brand

- Inverter: Mitsubishi/ JAPAN

- Motor: huangjie(more than 20 years of cooperation)

- Bearing: NSK/ JAPAN

Best Regards

Jenifer LIao/Vice President

.jpg)

www.sksprecisiontechtw.com

Whatsapp:+886-931166446

E: maquinas@ms77.hinet.net

(4).jpg)